Maintaining Safety and Efficiency: Pressure Vacuum Valves and Butterfly Valves in Tank Farms

Tank farms are vital in storing and distributing large quantities of liquids and gases, making safety and operational efficiency paramount. Among the key components ensuring both are pressure vacuum valves and butterfly valves. These unsung heroes quietly operate behind the scenes, safeguarding against potential disasters and optimizing the flow of materials.

Safeguarding Against Catastrophe: Pressure Vacuum Valves

A pressure vacuum valve (PVV) is the guardianof tank integrity. These unassuming devices prevent catastrophic events from over-pressurization or vacuum conditions within storage tanks. When a tank is exposed to rapid changes in temperature or sudden liquid withdrawal, a vacuum can form, potentially causing the tank to implode.

Conversely, over-pressurization due to various factors, including thermal expansion or delivery surges, can lead to ruptures. PVVs are engineered to automatically open when pressures exceed safe limits, releasing excess tension and preventing collapse or fracture. It protects valuable assets and averts environmental contamination and the risk of injury.

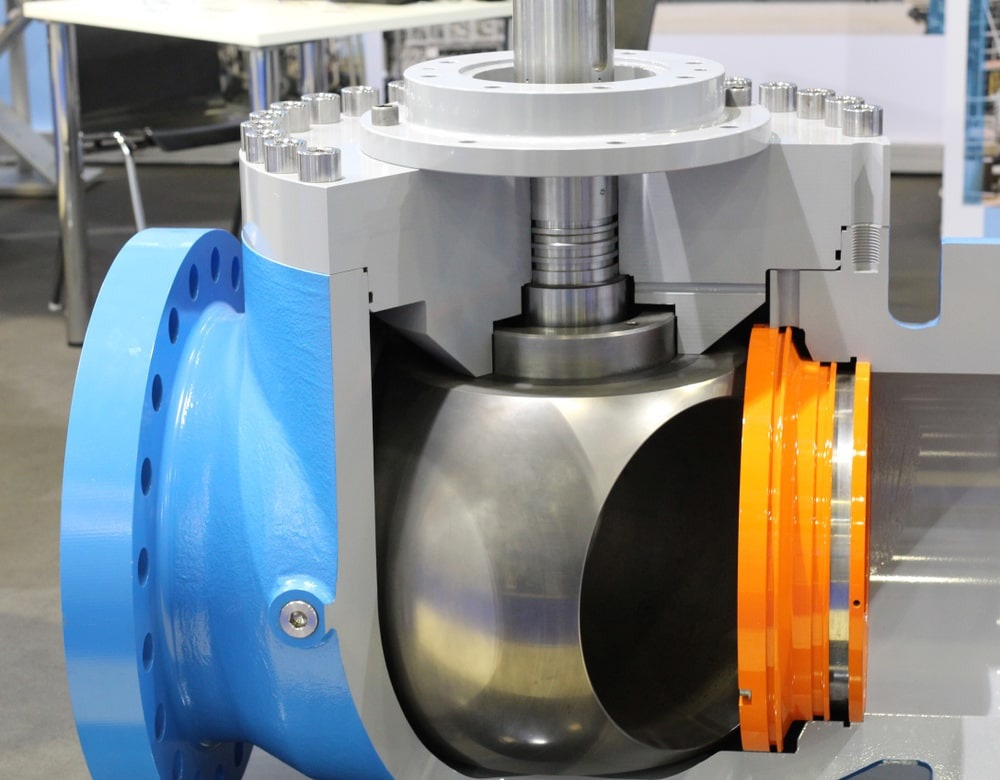

Flow Control at its Finest: Butterfly Valves

A butterfly valve, on the other hand, is the maestro of fluid flow. This versatile valve isolates or regulates the movement of liquids and gases into, out of, and within tanks. This butterfly valve shines when loading, unloading, and maintenance operations in tank farms.

Providing a robust and easily operated mechanism ensures smooth transitions between processes. Their ability to achieve precise flow control minimizes waste and enhances operational efficiency.

Real-World Impact: Case Studies

The significance of pressure vacuum and butterfly valves becomes strikingly clear when examining real-world scenarios. Consider a tank farm managing volatile chemicals. A sudden temperature drop can create a vacuum within the tanks, leading to potential implosion. The timely response of pressure vacuum valves prevents this disastrous outcome.

Similarly, during the offloading of a tanker truck carrying flammable liquids, butterfly valves efficiently regulate the flow rate, preventing spills, ensuring operator safety, and maintaining optimal efficiency.

Pressure vacuum valves and butterfly valves are unsung champions in tank farms. Their roles in preventing calamities, optimizing flow control, and enhancing efficiency are indispensable. The seamless synergy of these valves ensures the safety of personnel, the environment, and the operational integrity of tank farms.

As technology advances, these valves evolve, becoming smarter, more efficient, and better equipped to handle the demands of modern industrial processes.

To experience convenience, purchase efficient critical fluid transfer equipment with Treloar, a well-known Australian company that manufacturesqualityand well-grounded gears.